QuadFold @ IHF2025

QUADFOLD applied folding for timber plates

An experience in folding thin wooden plates. Inspired by students, supported by research and the FFG, fabricated by experts. Finally assembled and actuated by many helping hands.

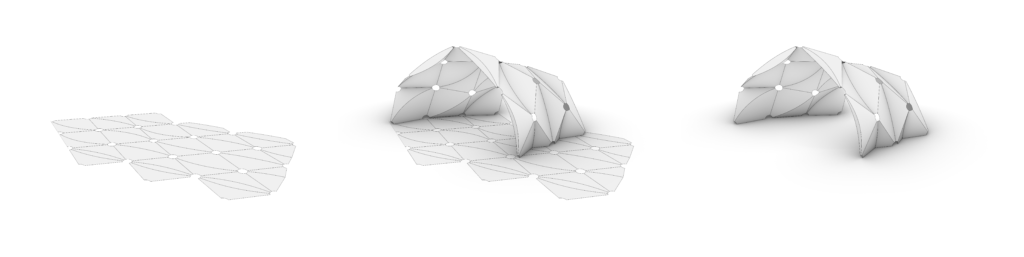

The Quadfold is an experimental structure that can be fabricated and folded from a single large sheet of material into its final form. It is one of the largest globally developable, foldable mechanisms made from wooden plates ever built. The mechanism consists of 40 foldable patches and measures 12 m × 6.50 m × 0.19 m in its planar state and 7.5 m × 5 m × 4.2 m in its folded state. The folded shell mechanism was developed using the Quadfill algorithm. This strategy enables the generation of globally developable surfaces from non-planar quads. Each quad is redesigned to consist of foldable patches derived from two cones, or from two cones and a cylinder. Each patch is connected by a curved fold line, while the quadrilateral patches are connected with straight fold lines.

The sheet of material consists of 19 mm laminated timber plates, connected with special hinges that allow rotation along their edges. The idea for these hinges was originally developed during a research-driven course at the i.sd – University of Innsbruck together with a group of students. The initial idea and the design of the structure also originated during this course. As the complexity of the entire approach was very demanding, the project was further developed by the research team of the “Plates 2 Structures” project into this demonstrator.

As a materialized manifestation of research-driven teaching, the QuadFold allows students to gain insight into state-of-the-art research and understand the relationships between material, fabrication and assembly of complex systems, by learning the limiting parameters of the material such as maximum bending radii or machining limits. The aim of the demonstrator is the exhibition of the significant potential of folded and bent structures from thin wooden plates to achieve structurally valid configurations. The flat assembly before actuating the structure on site reduces the transport volume, while maximizing the spatial possibilities. We want to thank the FFG for their outstanding support of the research and the industry partner Holzbau Saurer for the technical and scientific support as well as for their high fabrication capabilities. We also want to express our gratitude to the organizers of the IHF for the great opportunity to allow us and the students of the Faculty of Architecture to undertake such an experiment at this exceptional location.

Team: [i.sd] Marcus Bernhard, Ernest Hager, Rupert Maleczek, Klaus Oberwalder

[AB-Holzbau] Roland Maderebner, Thomas Hillberger

[die angewandte] Georg Lobe, Clemens Preisinger

[Holzbau Saurer] Roland Frehner,

[Supported by ] Jannik Deby, Choten Dorji, Marie Jurzig-Wetterkamp, Nils Klee, Franz Ladner, Ferdinand Lorentz, Michael Nagler, Fabian Quiring, Samuel Rimml, Jonas Thorn, Pema Wangchuck

Partners:

i.sd structure and design, university of Innsbruck

AB Holzbau,university of Innsbruck

die angewandte Holzbau Saurer

FFG Projektnummer : 50811776

Big Thanks to Ingrid and Uwe from Internationales Holzbau Forum for the possibilities to build in this incredible event, and to support the entire project !