Surface to Form Pavilion 2016

Surface to Form Pavilion 2016

– curved folded cone assemblies

Location: Innsbruck Austria

Client: university innsbruck

Gross floor area: 70m2

Year : 2016

Team : Rupert Maleczek, Guenther Filz, Christian Scheiber,

Moritz Heimrath, Clemens Preisinger

Partners: koge, Karamba, Europapier, university innsbruck

the challenge of folded Paper

The unit koge assembled in cooperation with Karamba 1200 curved folded paper elements to a large-scale demonstrator, showing the potential of process oriented design, digital simulation and fabrication in architecture. It explores the load bearing capacities of curved folded paper. The pavilion is part of successful series of experimental structures unifying basic research in computational geometry, material behaviour, digital fabrication methods and simple craftsman strategies to “architectural simplexities”. The structure was developed as part of a public exhibition at the University Innsbruck. The scientific publication can be found here.

Intelligent reduction for advanced stiffness

The development of the structure is based on the interdependency of curved folded elements, their assembly strategies and the relation to shell structures. The pavilions development is based on a simple fabrication

principle that is based on curved foldlines generated by complex geometric and mechanic constraints. The advantage of this particular system is an increasing stiffness through bending active behaviour by a simultaneous simplification in the fabrication through reduced number of necessary folds. The structure is one of the largest free standing folded paper objects that have ever been build.

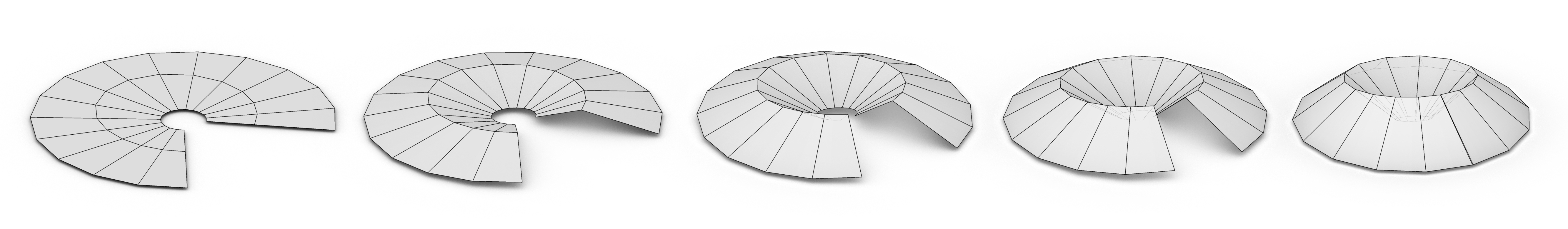

a curved folded cone (c) Rupert Maleczek

the cone generation on a given surface (c) Rupert Maleczek

(c) Michael Kraker

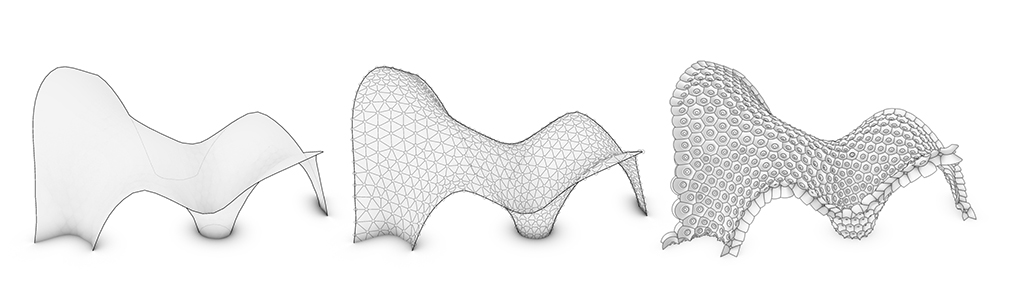

Curved folded Shell Structures

Based on the structural and spatial qualities of the conical folded

elements a strategy for the generation of comp lex geometries as well as an applied form finding process for this particular

strategy were developed. At the same time a fabrication technique was evolved, that enables extreme lightweight and performative segmented

paper shells.

The discovered potentials of curved folded cone assemblies are manifold.

The range of strategies allows the generation of thin shells with continuous thickness as well as double-layered structures with variant thicknesses.

The double layered prototype requires an advanced digital approach that allowed for the generation of a seamless pattern of cones in a three

dimensional design space. The seamless pattern consists of 1200 different cones, each generated individually based on geometric, static, spatial and

fabrication constraints.

Challenging paper

The combination of a simple strategy with a complex system generates a strategy entitled “simplexity”. This strategy enabled the development of paper, that is usually a representative to develop ideas and strategies based on other sheet materials, as load bearing structural material. The prototype represents an advanced computational folding strategy based and developed on paperplay.

The joy and ease of playing with paper combined with advanced knowledge in technical folding, form finding, architectural geometry and computational design enables a different way of fabricating space.

Dynamic Ornamentals

The design strategy performed by individually designed processes lead to a pattern of cones, with circular openings in the middle, that must be

described as a dynamic pattern, with excellent spatial, structural and lightning qualities.

The bespoke process enabled the generation of 1200 unique elements, that correspond with its neighbouring members, to build an irregular seamless pattern that composes a performative dynamic ornament. This dynamic ornament has excellent spatial, structural and lightning qualities. The combination of structural paper, and curved folded elements generated a complete architectural entity.

Design Aspects

The overall design was developed with site-specific conditions, and especially prepared as a demonstrator for the units exhibition contribution. The structure was designed to attract visitors to the two-storey high foyer of the faculty of architecture in Innsbruck, and invited people to explore the potentials of highly advanced processes in architecture expressed as a variation of paperplay. The geometry was designed and developed in a way that allowed a scale one investigation on the estimated design constraints. The structure has areas with double and single curvature, cantilevering up to 2 meters, three open columns and one entirely closed free-standing column and one cantilevering corner.

A Demonstrator on the Intersection of Architecture, Engineering and Paperfolding

The 1200 curved folded elements are fabricated from paper 0.75mm thick and 710 g/m². The overall structure weights 165 kg and covers 70 m². It spans 6.5 meters and is more than 6 metres high, and has only 2.1 kg/m². The pavilion was fabricated and assembled on site within 9 intense days.

Acknowledgments

koge – konstruktion und Gestaltung | Institut für Gestaltung | Universität Innsbruck

Rupert Maleczek, Guenther Filz & Christian Scheiber

Karamba

Moritz Heimrath & Clemens Preisinger

Workshop

Ernest Hager & Klaus Oberwalder

Students

Barbisch Melissa, Dengler Carmen, Egger Carmen, Egger Robert, Halder Moritz, Hanakam Christine, Hanifle Alexandra, Hofer Sophia, Hoffmann Tobias, Holger Reinhard, Hoffmann Vincent, Hornsteiner Verena, Jenewein Benjamin, Kappacher Marie Therese, Kraker Miachel, Lemarie Marine, Maric Sanel, Mayr Thomas Emil, Moosbrugger MariaJin Ying, Moosmann Magdalena, Neuwirth Sabrina, Oberlechner Thomas, Oberholzer Theresa, Röck Kerstin, Rungg Andrea, Schieder Pamela, Schömann Christoph, Schwarz Christoph, Sponring Anna, Theer Luca Mario, Trobos Mathias, Tschigg Evelyn, Wirion Charles, Wolfensteiner Balthasar, Wolf Pia, Omid

(c) Rupert Maleczek